Herstellung, Reparatur und Ersatzteilfertigung

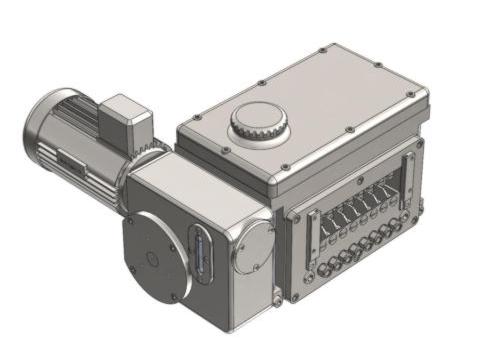

Image shows a Roesen Box Lubricator system Gruetzner EZ VIII with a gearbox

Image shows a Roesen Box Lubricator system Gruetzner EZ VIII with a gearbox

Roesen Box Lubricator model EZ

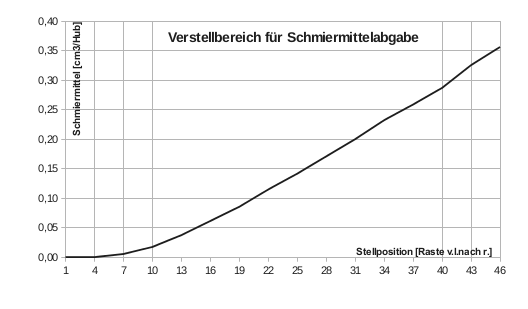

This sophisticated model system Gruetzner EZ is built for lubrication with oils and emulsions up to 2170psi counter pressure. It is characterized by a third piston valve which ensures gas free fluid flow. Depending on the design it provides up to 20 indivi- dually adjustable lubrication points with a feed rate up to 0,02in 3 per stroke/point. All oils and emulsions with a viscosity range from 25 to 3000 cSt – also food grade oils – are usable. Box Lubricator Gruetzner model EZ for up to 2170psi

Due to the modular design and “Pump-to-Point” of the Roesen Box Lubricator EZ we can customize to a large variety of plants and drive systems. Because of the forced control of conveyor and me- tering piston a Roesen Box Lubricator is ensured to run up safely – also after a longer downtime.

Image shows a Roesen Box Lubricator System Grützner EZ II

Box Lubricator Gruetzner model EZ for up to 2170psi

• housing, pump body and crankshaft

bearings are made of cast iron (EN-GJL-250)

• suitable for oils and emulsions

• force controlled

• unpressurized visual control

• precisely adjustable

• designed for economical, reliable

continuous operation

• drive systems:

rotating, oscillating or motor driven

• up to 20 lubrication points

• flow rates up to 0,02in 3 per stroke / line

• up to 2170psi counter pressure

• includes test certificate according to DIN EN 10204-3.1

Specially designed models:

• with Flow-Switch• with overpressure valve

• with pre lubrication system

• with heating system

• with ATEX realization

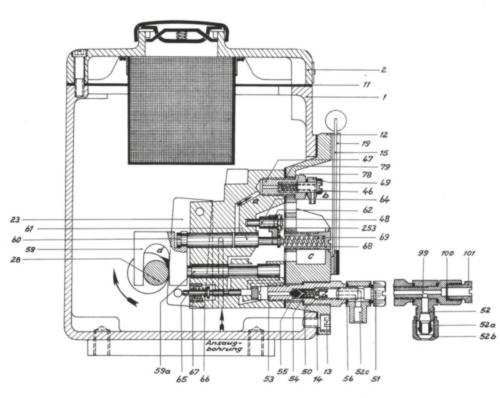

Roesen Box Lubricator EZ function

The control piston (61) follows the in-stroke of the allocating piston (60) until it reaches the adjustable stop, provided by the carrier (62). Depending on the detent position of the regulation screw (64) a vacu- um develops which sucks up oil, indicated by the direction of the arrow, into the cylinder. There will always be more oil sucked up than needed. Excess oil is sent back to ensure a compensation of the flow rate of different viscous oils. The oil is pumped to the visual flow control (b) where it visibly returns to the control basin (c) of each lubrication outlet and is accessible for flow calibration. The control basin (c) feeds the pump piston (59a) with oil which is provi- ded over the piston valve (65) to the outlet (52). After the pump stroke is completed the piston valve (65) is mechanically closed through a lever (23), actuated by a cam (d) on the camshaft (28). Any kind of oil slippage is conducted by relief grooves in the pump piston (59a) and piston valve (65) back into the control basin (c). Therefore any unregular pump activity is visible.

Diagram shows a Roesen Box Lubricator system Gruetzner EZ II

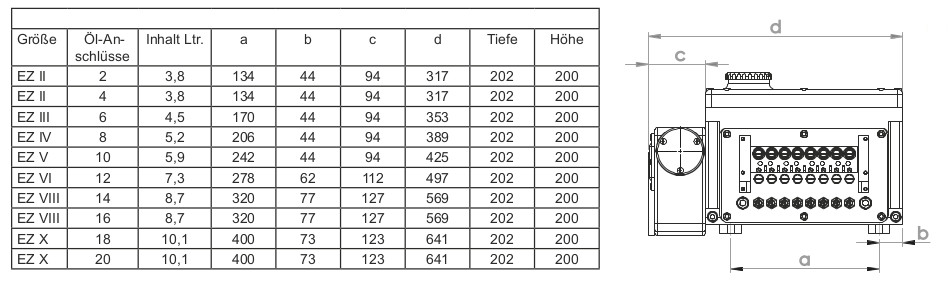

Model EZ case designs

Model EZ drive versions

Transmission drive

The transmission can be adapted to customer needs with different gear ratings. The drive shaft can be fitted with different adapters and diameters. The input shaft can be placed up- / downwards, front- / backwards or to the side. The transmission can be mounted on the left- or right- hand-side of the lubrication box. This makes it possible to drive the system by chain, gearwheel, coupling or a belt.

Motor- / Transmission drive

A matching electric drive with an adaptable mounting position can be configured to confined spaces. The motor can be delivered with one- or three-phase power connection. Special versions support the adjust- ment of variable engine speeds.Technical realization conform to ATEX directives are available.

Oscillating swing arm drive

The oscillating swing arm is used to drive the lubrication pump for an al- ternating drive and can be mounted on the left- or right-hand-side. This is used for example for stuffing lubrication on plunger pumps.Model EZ optional equipment

• All available versions (transmission-, motor- or oscillating swing arm)

can be fitted with a hand driven prelubrication.

• Pump outlets are delivered with 6mm, 8mm, 1/4” solderable

or compression fitting.

• All pump outlets will be fitted with high quality check

valves for maximum operational security.

• Furthermore all outlets can be equipped with oil returning

pressure relief valves.

• Function monitoring can be provided by our optional

built in Flow-Switch.

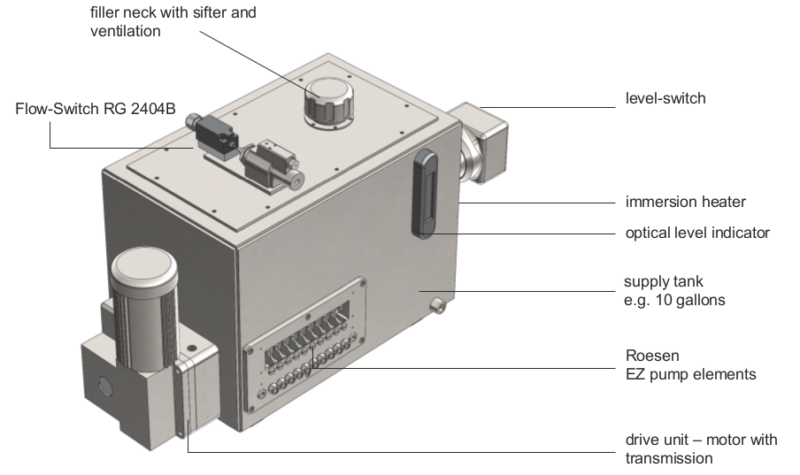

Roesen EZ compact oiler

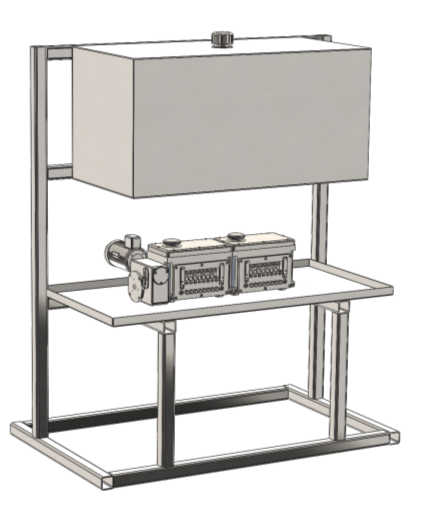

Roesen EZ Standalone-System

We offer centralized lubrication units as Stand-Alone systems. The main elements of this system are the Roesen EZ II to EZ X Box Lubricators. A combination of Roesen EZ and HD are possible. The lubricant reservoir will be customized in size and layout to your needs and provided with the right lubrication system as a whole unit. Supply of lubrication from the reservoir is provided by gravitation. Optional components are optical and electrical temperature- and fill level monitoring devices as well as a heating system. On request we will provide you with a redundant lubrication unit. Our pump systems are configured by default for reliable “Pump-To-Point” lubrication. If desired the system can be adapted to Progressive Divider or Divider Block systems.